Redshift works with local and international vendors for thermal desorption systems.

This includes complete technical and financial analysis of the proposed unit.

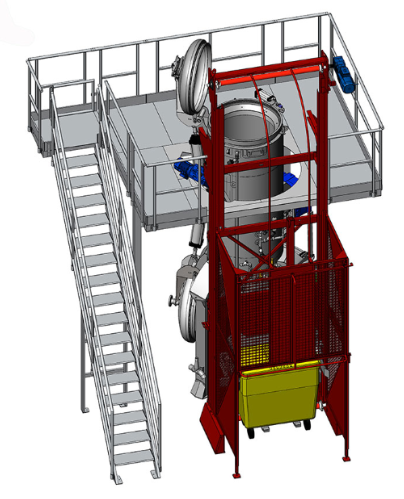

For Medical & Hospital waste, Redshift’s selected Autoclave process is designed to shred and sterilize infectious waste by saturated steam. Shredding and sterilization are achieved in one fully enclosed and automated, stainless steel, system with no intermediate waste handling. The contaminated waste is loaded into the upper chamber where a heavy-duty shredder reduces the waste into small pieces. Using gravity, the processed material drops into the lower treatment chamber. After shredding, waste and all the inner parts of the machine are steam heated to 138°C (280 F) and pressurized to 3,5 bar (51 psi). Sterilization is achieved by maintaining a temperature of 138°C (280 F) at the core of the waste for 10 minutes.

After the cooling process, the final product is safe to recycle or to dispose of as ordinary waste. Waste is both sterilized (Microbial inactivation = 108) and volume reduced by up to 80 %. The duration of an average cycle process is fully automated and totally monitored. A computerized control system scans the process and automatically prints and records on a memory card a batch report at the end of each cycle with the essential sterilization parameters for accurate record keeping. Disinfected waste is disposed off in a scheduled landfill.

Our core values center around environmental responsibility, client focus, and ethical conduct. These values are embedded in our approach to contracting and environmental solutions.